Custom production

At OLARRA, we know that each customer needs a product with custom features. And that each application can achieve a better performing steel. Therefore, we have focused on custom production. We work with each of our customers to design and define the product that best adapts to their needs.

We therefore having a highly qualified human team who analyses each order to search for the most appropriate product. Elements such as the AOD converter means we can precisely adjust the chemical composition of the steel according to our customers’ requirements. The great variety of thermal treatments, finishes and measurements adapts to the requirements of all our customers and achieves an optimum performance of the final product.

Types of stainless steel

Austenitic

Martensitic

Ferritic

Duplex

Heat-resistant

Precipitation hardening

Size range and profiles

Round 3 – 100 mm

Cold drawn hexagonal 10 – 70 mm

Cold drawn square 6 – 58 mm

HRAP square 22 – 60 mm

Hot rolled billet 40 – 80 mm

Wire rod 5.5 – 32 mm

Dimensional tolerance

h8 /h9 / h10 – EN 10278 / ASTM A484 bright round

k12 /k13 – EN 10060 /ASTM A484 hot-rolled round

h11 – EN 10278 / ASTM A484 cold drawn hexagonal and square

HRAP – EN 10059 pickled square

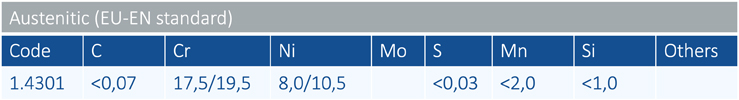

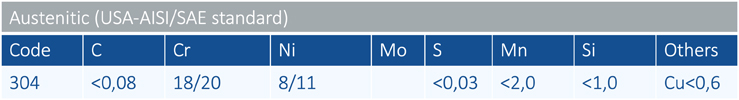

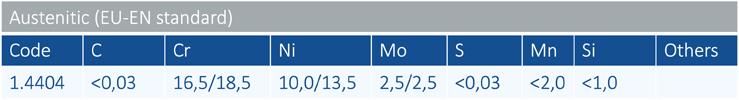

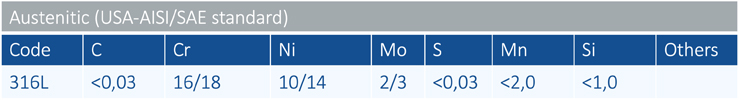

Austenitic

Austenitic stainless steels are known for their highly corrosion resistance and good weldability. They have high mechanical properties when cold formed, but they are, in principle, more discrete compared to other stainless-steel families.

· Application examples:

Household sectors, durable consumer goods, food industry, chemical, petrochemical, nuclear, paper industry, construction, transport by land, sea and air, health applications and environment.

· Typical steels:

1.4301/AISI 304

1.4404/AISI 316L

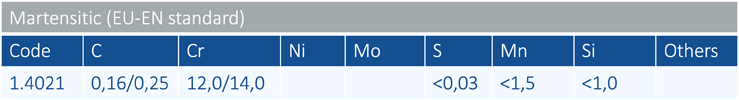

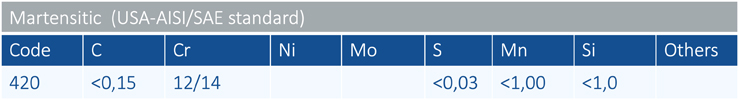

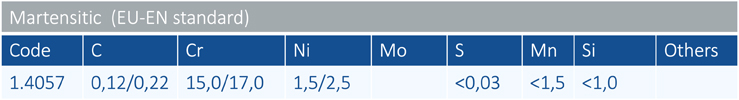

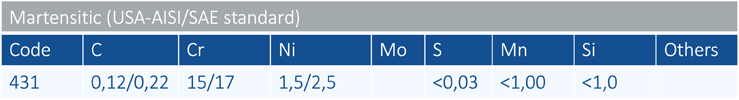

Martensitic

Martensitic stainless steels have high mechanical properties, with heat treatment can increase further. Their corrosion resistance is more limited compared to other stainless-steel families.

· Application examples:

Cutting instruments, springs, bolts and nuts, and fasteners.

· Typical steels:

1.4021/ AISI 420A

1.4057/ AISI 431

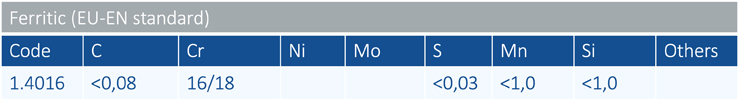

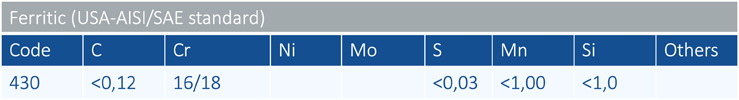

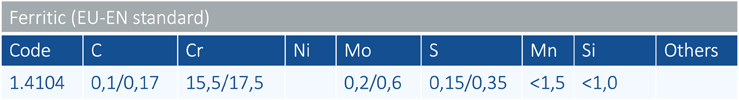

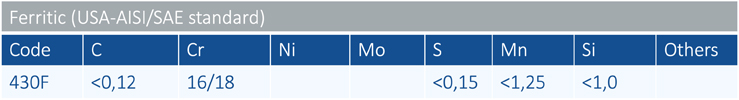

Ferritic

Family of stainless steels that are good for cold forming. A high percentage of chrome can lead to better corrosion resistance at high temperatures.

· Application examples:

Household appliances, interior furniture, components for thermal devices, transport chassis, construction and agriculture sectors.

· Typical steels:

1.4016/ AISI 430

1.4104/ AISI 430F

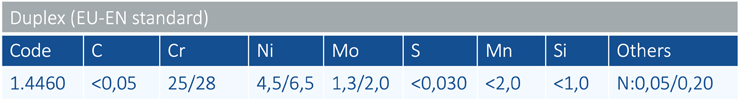

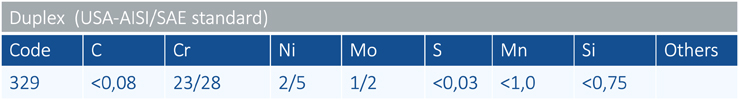

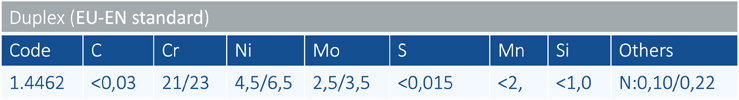

Duplex

Duplex or austenitic-ferritic steels are highly corrosion resistant, particularly in environments where most tension is generated. They also offer high mechanical resistance.

· Application examples:

Sectors of the chemical, water treatment, oil extraction and processing, and heat exchanger industries.

· Typical steels:

1.4460/ AISI 329

1.4462/ F51

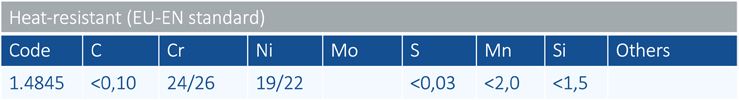

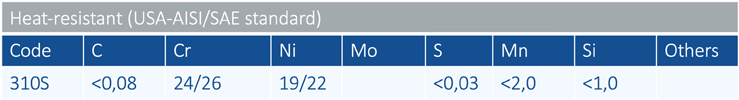

Heat-resistant

Heat-resistant steels are mainly used for processes that require great resistance for high temperatures, around 1000 ºC.

· Application examples:

Industrial applications, heat treatment furnaces, air heaters and electrical resistors.

· Typical steels:

1.4845/ AISI 310S

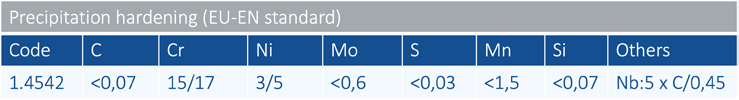

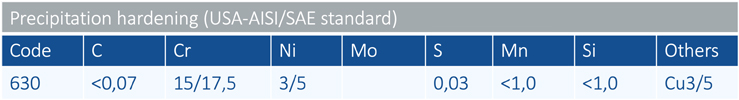

Precipitation hardening

They are highly corrosion resistant and have high mechanical properties, that can be increased using thermal age hardening.

· Application examples:

Structural elements for aircraft and naval means.

· Typical steels:

1.4542/ AISI 630